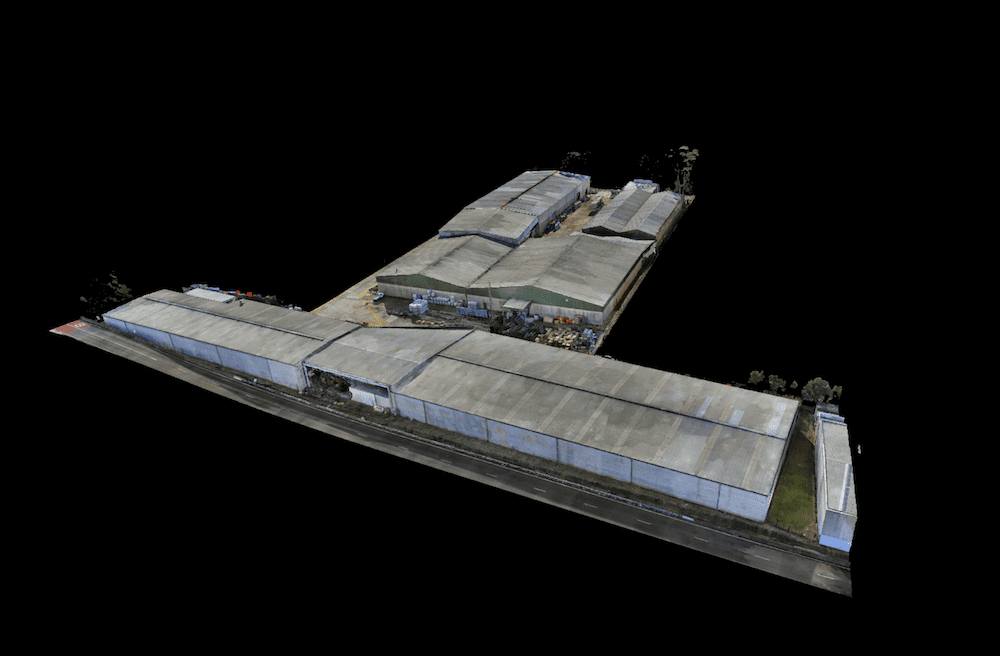

High Exposure was enlisted to conduct a comprehensive roof inspection for a 20,000m² warehouse as part of a due diligence process before the property’s purchase. The primary goal was to determine the condition of the roof, and the client required high-detail imagery and a 3D model for a thorough and efficient assessment.

Objective:

The main objective was to leverage drone technology to perform a swift yet comprehensive inspection of the warehouse roof. The deliverables included high-resolution imagery of the entire roof, a 3D model for easy navigation and defect assessment, and an online 3D model viewer with georeferenced images for accurate measurements and annotations.

Methodology:

Drone Technology:

- Deployed drones equipped with high-resolution cameras to capture detailed imagery of the expansive 20,000m² warehouse roof.

- Utilied drone technology for a quicker, safer, and more comprehensive inspection compared to traditional methods.

3D Modeling:

- Employed advanced photogrammetry techniques to create a highly detailed 3D model of the warehouse roof.

- Ensured that the model accurately represented the structure, allowing for easy navigation and defect assessment.

Geo-referencing:

- Geo-referenced all captured images to maintain spatial accuracy in the 3D model.

- Integrated GPS data to ensure precise alignment of the 3D model with real-world coordinates.

Online 3D Model Viewer:

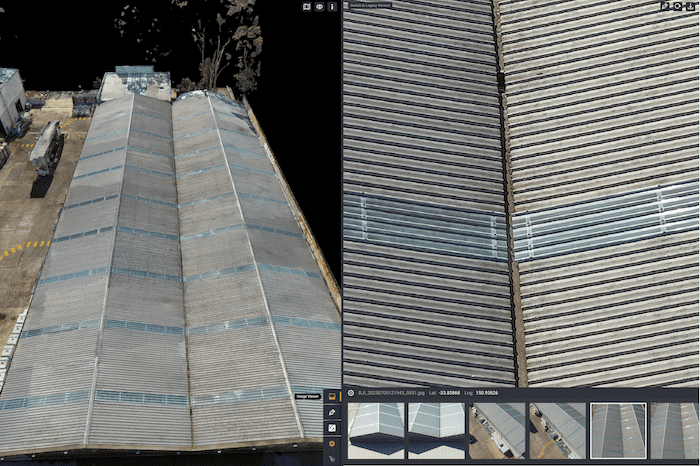

- Developed an online 3D model viewer that allowed stakeholders to navigate the 3D model easily.

- Geo-referenced all images within the viewer for accurate measurements and annotations.

Execution:

Data Capture:

- Conducted drone flights to capture high-detail imagery of the entire 20,000m² warehouse roof.

- Utilised the drone’s capabilities to access difficult-to-reach areas, ensuring a comprehensive inspection.

Photogrammetry Processing:

- Processed captured imagery using photogrammetry software to generate a detailed and accurate 3D model.

- Ensured that the model reflected the actual condition of the roof, enabling defect assessment.

Geo-referencing and Online Viewer Integration:

- Integrated geo-referencing data into the 3D model and the online viewer, ensuring spatial accuracy.

- Enabled stakeholders to access the model online, facilitating collaborative decision-making.

Image Embedding:

- Embedded high-resolution 2D images into specific points of the 3D model, allowing users to click on any area for a detailed view.

- Eliminated gaps in knowledge by providing a complete and detailed perspective of the roof.

Results:

Comprehensive Inspection:

- Delivered a thorough roof inspection with high-resolution imagery and a detailed 3D model, providing a holistic view of the warehouse’s condition.

Confidence in Due Diligence:

- Empowered the client with confidence in their due diligence process, thanks to the speed and comprehensiveness of the drone inspection.

Online Collaboration:

- Enabled stakeholders to collaborate online using the 3D model viewer, facilitating discussions and decision-making.

Exportable Reports:

- Produced exportable reports from the online viewer, allowing stakeholders to share the inspection findings with ease.

Conclusion:

High Exposure’s drone roof inspection for the 20,000m² warehouse not only expedited the due diligence process but also provided a level of detail and accessibility that traditional methods could not match. The integration of high-resolution imagery into the 3D model, coupled with geo-referencing and online collaboration tools, created a seamless and comprehensive solution for the client. This case demonstrates the transformative impact of drone technology on due diligence processes in real estate, offering efficiency, accuracy, and confidence in decision-making.